Introduction

The involvement of the Dobson name in boatbuilding can be traced back to 1876 when Henry Dobson completed his apprenticeship with Henry Dickinson of Burton on Trent and it is believed that the family was responsible for the running and maintenance of the River Trent Ferry in Burton from about 1887 as well as the production of fishing boats for the gentry and craft for the Rowing Clubs in the East Midlands.  ferry across River Trent at Burton on Trent Various premises were used in Burton on Trent the last being sited in the Horninglow basin at the beginning of the 20th century. Progress here was restricted by the widening of the A38. Upon the return of John Dobson from his service in the Royal Navy, the company decided to seek a new site.

ferry across River Trent at Burton on Trent Various premises were used in Burton on Trent the last being sited in the Horninglow basin at the beginning of the 20th century. Progress here was restricted by the widening of the A38. Upon the return of John Dobson from his service in the Royal Navy, the company decided to seek a new site.

Burton yard, Horninglow, Trent and Mersey Canal.

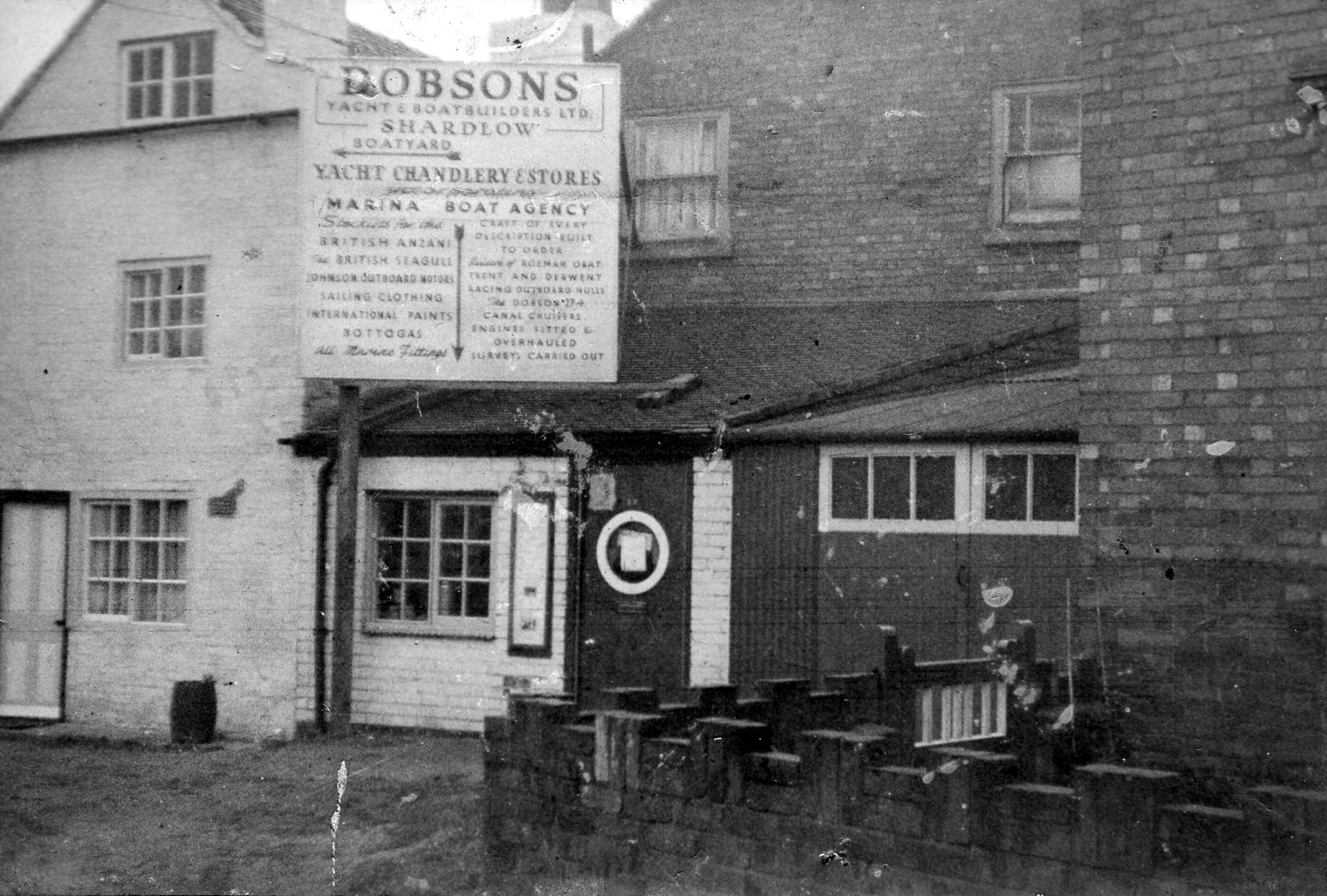

The site chosen was downstream from Shardlow Lock in the canal port of Shardlow. Whilst there had been boatyards and builders in Shardlow at the height of the commercial success of the canal system in England, none remained in the late 1950s. John Dobson and his father Cecilchose an unused area alongside the Trent and Mersey Canal between the Mill buildings of F. E. Stevens corn merchants.

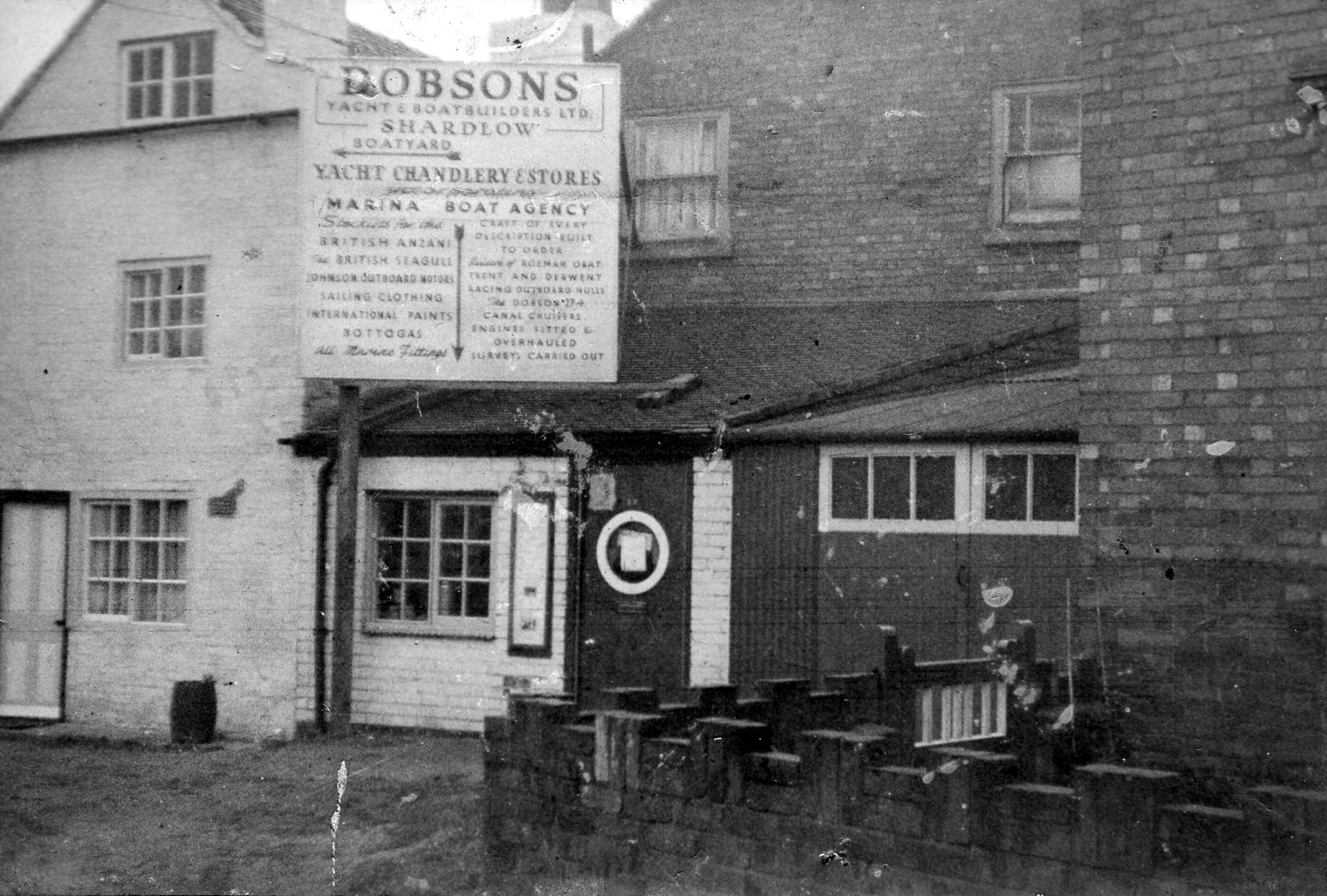

Shardlow yard, Trent and Mersey Canal.

The site at Shardlow provided space for a large purpose built covered workshop with two slipways leading into building areas for up to five craft from 24 feet to 60 feet in length.

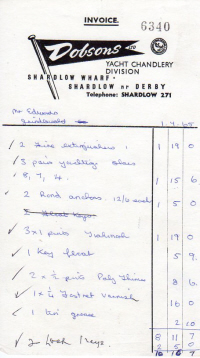

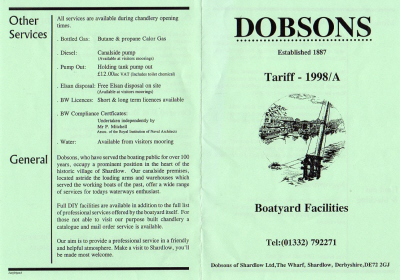

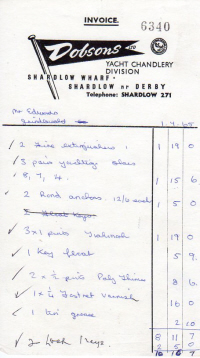

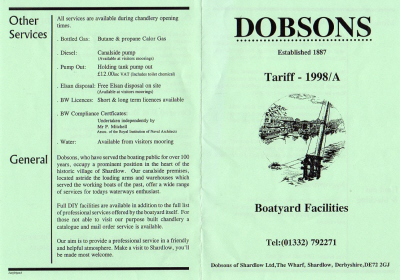

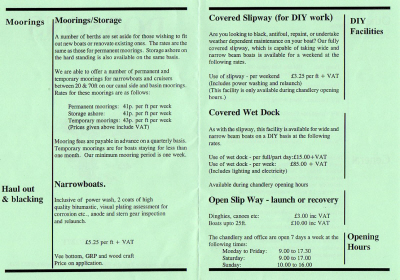

To provide further help to the boating public, a chandlery and outboard and inboard engine service base were set up in a building on the wharf accessed from the Twitchell or Wilne Lane. This became the main distribution point in the East Midlands for Marine paint which was supplied to a large number of boatyards on the canal system.

Chandlery, the Wharf, Shardlow

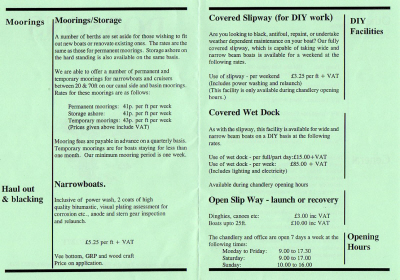

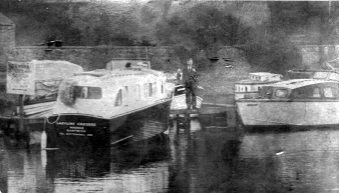

Moorings for private use were provided with finger stagings utilising the main canal frontage as well as the original canal loading and offloading basins.

Moorings, Shardlow

BOATS

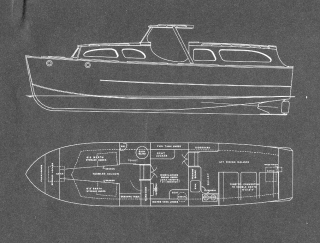

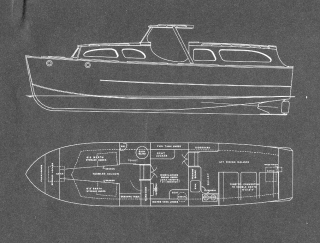

During the period 1945 to 1955 production was limited to modification of existing wooden wide beam craft to provide inland river cruisers and carvel built hard chined narrow beam cruisers built from scratch. The majority were powered by petrol enginesprofessionally modified for marine use and varied in length from 20ft to 30ft.

Hull planking and plan for a cruiser.

A 38ft luxury narrow beam cruiser for use in the rapidly developing canal holiday cruising business.This was one of the first boats in to the fleet of Ladyline in 1961.

The mid 1960s saw the development of the bluff bowed butty style cruisers and the production of one of thesefor a Harley Street surgeon. It was built to the extreme standards of Lloyds 100A1 utilising teak planking on oak framing and powered by an inboard Mercruiser diesel engine connected to an outdrive.

The market widened further to the production of examples of estuary sailing cruisers like the Eventide 24 drop keel 4 berth yacht.

Mouldings produced by Colvic Plastics were utilised for the production of 35ft ketch rigged sailing cruisers for use in the North Sea and Channel areas.

Island Plastics moulded hulls were utilised for production of the IP24 which were exported to Holland and Switzerland as gaff rigged inland lake and estuary cruisers.

Sailing dinghies During the 1960s and 1970s there was a further widening of the types of craft produced to include a range of sailing dinghies of National and International regulations. The early models were constructed in timber with later craft utilising a mixture of glass fibre hulls with wooden trims. These established Dobson Yacht and Boatbuildersas a leading producer of sailing dinghies for use on inland lakes and resevoirs as well as river and estuary. The classes built included the Eleven Plus, International Moth, Scorpion, Solo, GP14, Fireball, Heron and International Optimist. Following the attendance of John Dobson on a trade mission to North America the company began a close relationship with the GP14 Class Association in the USA and Canada and commenced delivery of both complete boats as well as spare parts in container loads.

|  |  |

| Scorpion and GP14 | G14 construction | dingies for export |

Under the control of Ann Williams and John Leask the existing Chandlery was further expanded by the development of a Mail Order Service to meet requirements of boat owners fitting out their own craft. The Company was also appointed a specialist in Osmosis treatment for glass fibre hulled craft by Blakes paints.

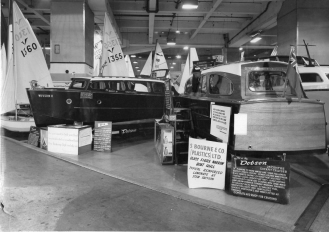

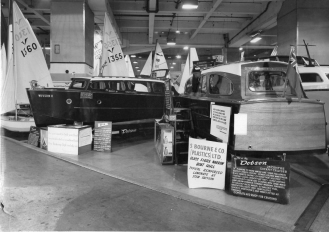

Boat Shows Dobsons commenced showing the results of their skillful design and finish at the 1965 International Boat Show in Earls Court and demonstrated the wide range of product for over 30 years at the London, Birmingham and Nottingham shows as well as supporing the IWA National Rally.

|  |

|

| 1967 | 1979 |

|

With the retirement of John Dobson to Falmouth, the Company continued under the Chairmanship of Philip Mitchell and the remaining Directors, strengthened by the addition of Keith Case and Stuart Emmerson. The latter were involved in Sherwood Canal Hire Boats based at Shardlow under a long term agreement which enabled the two companies to join forces.

Wooden and fibreglass boats. Distinctive looking estuary class boats were built throughout the 1960s for river and estuary work. Most of these craft were constructed with mahogony planking, copper rivetted to an oak framework with the cabin areas built in marine plywood, with mahogany furnishings and flooring. The 1970s saw the gradual reduction in wooden craft and the development of glass reinforced fibreglass mouldings. Dobsons, in co-operation with the Nottingham company of Bourne Plastics, developed a range of cruisers from 24ft to 40ft. Also produced were a range of wide beam fully cabined craft suitable for the hire boat market. The Saxon moulded by Bourne Plastics led to a contract for a number of hire cruisers provided by the Guiness Company for use on the River Shannon, Ireland.

The smaller craft produced in this range were completed with a moulded cabin structure for both centre and aft cockpit styles. The majority of these craft were powered by small diesel engines.

|  |

| Estuary Class boat under construction | Assembly of GRP mouldings for Saxon class |

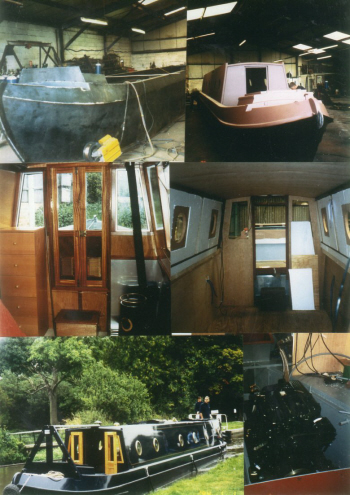

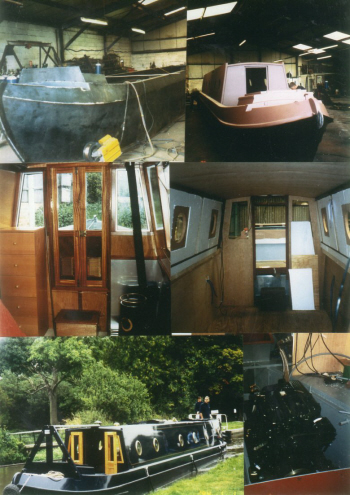

Steel Hulls Market pressures in the 1980s once again dictated major changes in production of the waterways cruising vessel. The pressures were partly financial and partly constructional. The constructional strength and durability of a steel hull when used during locking was far in excess of both wooden and glass fibre hulls and the overall costs of production in steel were considerably less. As with the wooden and glass fibre craft, the styles included aft cockpit, cruiser and traditional designs with both narrow beam and wide beam options available. There were a number of wide beam craft produced for use as trip boats on both the River Thames and Scotland. Clients began to dictate their preferences, as fabricators improved their skills in construction and design, allowing the fitting out to be the result of close co-operation between the company fitting out and the purchaser. Dobsons had developed a keen sence of what the customer wanted, and offered a high quality and competitive service in design and detail to suit. At first the major parts of hull construction, cabin and decking were undertaken in Shardlow but the undercover space required for both steelwork and fitting out was very restricted. The inland waterway market was surging and steel fabrication outlets soon began to ease Dobson's problems by offering a fabrication service for completion by specialist fitters.

Traditional wooden boat repairs Whilst there was a steady flow of newly built craft this was interspersed with a considerable amount of repair and renovation work on existing craft. The specialist boatbuilders employed were well able to undertake planking and cabin repairs to a high standard.

|  |  |

| preparation of cabin side | caulking | replace roof and decks |

|  |  |

| complete refurbishment | replace planking | repair ribs |

Lengthening steel narrowboats There was an upsurge in the market for lengthening steel narrowboats which provided development in new skills. As a result customers were able to retain their original craft but modify the accommodation to suit an expanding crew or to provide more comfort and luxury or both.

Psalter - a 45 foot Sagar steel narrowboat being lengthened by 12 feet

Psalter - a 45 foot Sagar steel narrowboat being lengthened by 12 feet Some documents

| VisitShardlow and its Heritage Centre for a fascinating insight into this 18thcentury canal transhipment port. Follow the village trail, on sale at theHeritage Centre! See our home page. |

LINKS TO OTHER PAGES IN THIS SITE